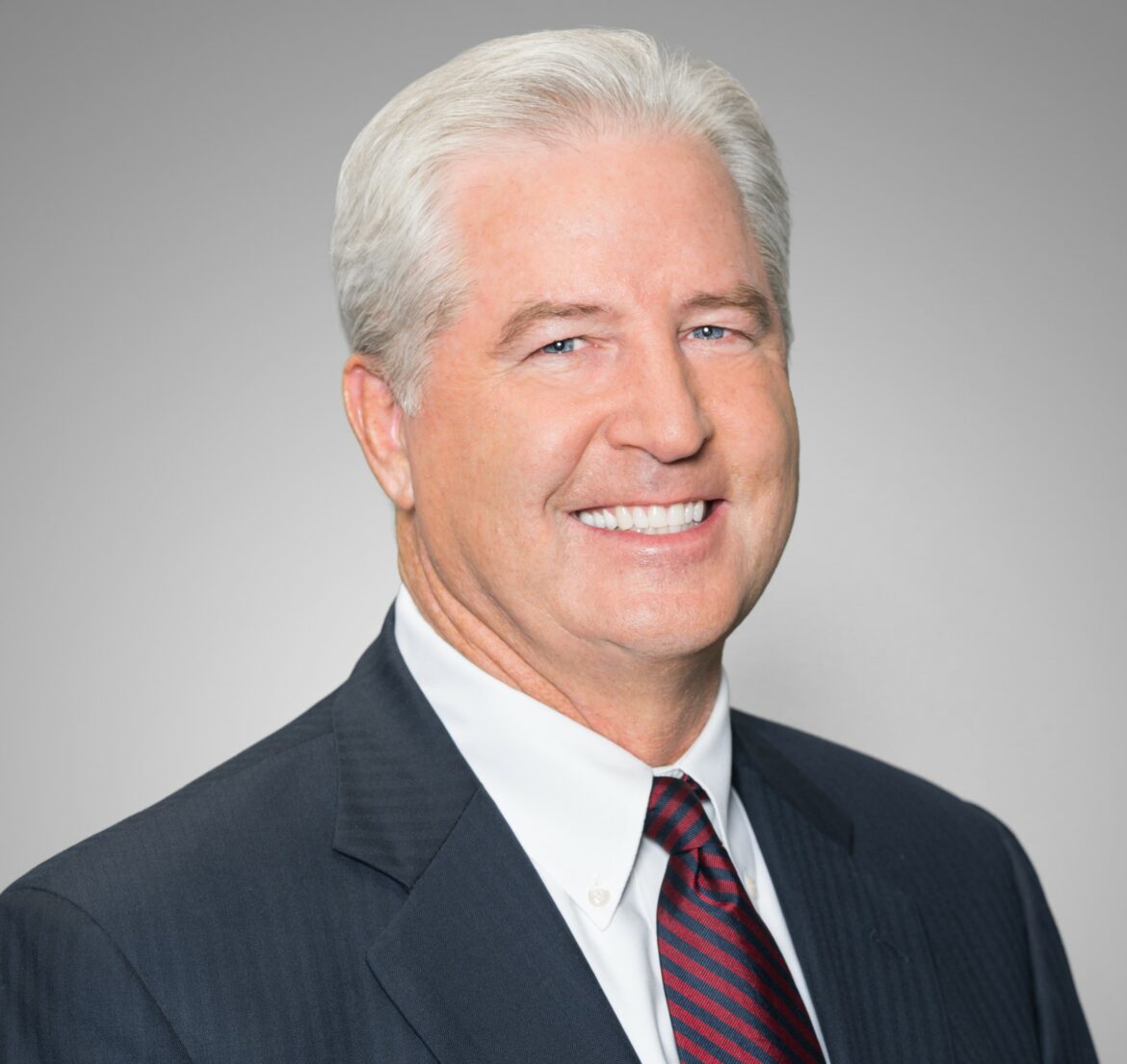

How are the supply chain crisis and backorders doing as of March 2023? To answer that question, we contacted three OEMs to get their take on the situation. In our second installment, Steven Tungate, vice president & general manager, service, supply chain, and innovation for Toshiba America Business Solutions, responds to our questions.

What’s the status of your backorders as we enter March 2023?

Steven Tungate: Backorders have been reducing greatly throughout the last few months, and we expect more improvement by March. About 90% of our models are no longer on backorder and the remaining models are experiencing fewer logistics issues than we’ve had in the past.

While nearly completely transitioning to our next-generation e-STUDIO multifunction printers, some temporary backorder situations may occur. We are managing the new product introduction by closely collaborating with our dealers to understand demand, timelines and alternatives to ensure we meet or exceed client expectations.

Toshiba made a wise decision many years ago to produce toners for all of the Americas from our manufacturing plant in Mitchell, South Dakota. Toner is the most critical commodity within our chain. During the height of the global supply chain crisis, we did not have any Toshiba toner backorders or delays to our clients.

What’s the biggest lesson your company has learned from the supply chain disruptions of the past two years?

Steven Tungate: The pandemic-related supply chain disruption was unlike anything I’ve experienced during my 35+ year career. While I’ve seen many specific industry disruptions, I’ve yet to see one across the board for all businesses. Impacts relating to components, production, logistics, and client behavior occurred. The perfect storm, if you will.

That said, we did discover ways to build and implement flexibility and adaptability measures to protect the continuity of supply. One result was changing production locations to lessen the disruption in any particular region by increasing production elsewhere. This strategy facilitated the continuity of supply while lessening costs.

Product production in China includes a 7.5% import tariff. Costs that we simply cannot pass on to our clients. By improving our development processes relating to forecasting and fulfillment, we ensure building the right product at the right time to meet specific client demands.

We also created processes to increase our visibility. We now know where products are located within the pipeline. Whether it is on a container in the ocean, a rail car, a truck, or on a plane. We’ll always remember the lessons learned over the last two years. The result is a better and, overall, more resilient supply chain for the future.

How have last year’s supply chain disruptions prepared your company should a similar situation occur again?

Steven Tungate: We immediately communicated our supply chain challenges to our stakeholders. Our primary focus is always to share information with our dealer sales and client support personnel. They can best identify current information relating to product availability while conveying updates to resellers and end users.

As the pandemic disruptions extended from weeks to months, we began to reach further back into the supply chain to understand the disruptions, counter measures, and recovery plans. New processes for daily communication between manufacturing, planning, and sales are now standard practice today.

While much more prepared, we strive to improve even further. We’re continually working to adopt more flexibility and visibility while ultimately improving our process. In Q1, we’re already adopting new communications capabilities. Though we can’t prevent a pandemic, we are operating more resiliently while improving communications across the supply chain.

With the supply chain flowing again, what products are in the pipeline for the next few months that will excite your dealers?

Steven Tungate: The pandemic did disrupt the launch of our next generation of e-STUDIO MFPs. This transition is almost complete, and our new products are Toshiba’s best ever! Our latest MFPs are designed as an onramp for many new workflow solutions, all the while increasing value for our dealers and clients alike. The line delivers significant new capabilities in serviceability to lower service costs while improving client uptime and satisfaction. All of which ultimately improve profitability for our dealers.

_________________________

To become a subscriber, visit https://thecannatareport.com/register or contact cjcannata@cannatareport.com directly. Bulk subscription rates are also available upon request and included in our media kit.