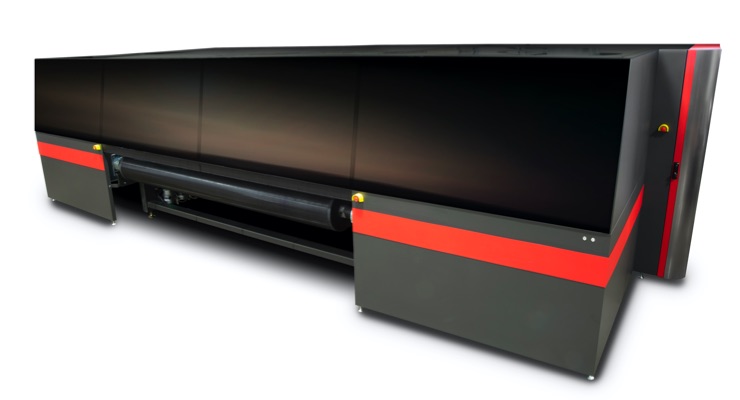

Electronics For Imaging, Inc. (EFI) reported that Nashville-based print fulfillment and distribution business Ingram Express Services (IES) has installed the world’s first EFI VUTEk XT hybrid flatbed/roll-to-roll display graphics printer. IES eagerly invested in the new super-high-speed solution to expand its VUTEk-heavy digital graphics production floor and venture into new market opportunities, addressing a growing demand for higher-volume rigid substrate work.

The new VUTEk XT printer is built on an entirely new platform, designed for unmatched throughput and print capabilities, litho-like image quality, and unparalleled ink yield to help sign and display graphics providers win more profitable business and expand their applications. It is an exceptionally versatile solution that delivers outstanding results on signage media, as well as on corrugated board for high-end packaging and display applications.

“The VUTEk XT is going to change us in many ways, the biggest being pressroom disruption,” said IES Owner Adam Ingram. “Our capacity is going to go through the roof compared to where we are now.”

IES purchased its first EFI printer in 2016. Now, along with the new XT model the company runs two hybrid and two roll-to-roll VUTEk systems – including a second VUTEk Q3r roll-fed UV LED inkjet printer installed earlier this year.

“Our market’s changing because we’re changing,” said Ingram. “With the VUTEk XT we’re expanding our market. Our footprint is going to change.”

The VUTEk XT printer is designed to drive a significant reduction in total cost of ownership with superior throughput exceeding 350 boards per hour. A new vacuum architecture on the VUTEk XT printer offers five times more hold-down for a wide range of materials. A new media transport eliminates the need for material edge guides, ensuring highly accurate registration and smooth transport of even thick boards. These advanced features make printing traditionally difficult substrates easier and more accurate, reducing waste and improving overall throughput.

“Our customers are looking for faster turnaround at better cost,” said Ingram. “We’re in a time now where material costs are through the roof so customers are looking for everything they can and efficiencies matter.”

The VUTEk XT printer’s exceptional throughput will enable IES to manage costs, meet customer turnaround requirements, and take on large jobs that would have previously slowed the entire production floor.

“In wide format, large jobs – while they’re great – can be very scary because you can get them in and all of a sudden you think this is a 12-15 day run,” explained Ingram. “Now, for us, those jobs will be 2-3 days max, so we’ll be able to turn more jobs out in a quicker span.”

A multi-lane printing feature on the new VUTEk XT model offers users the option to feed boards in up to three printing lanes, using the same or different print files. The VUTEk XT supports roll-to-roll printing of large rolls up to 59 inches (1.5 meters) in diameter with two independent drives for two-up printing, or one collaborative drive for one-up printing.

Enhanced dual-zone Pin & Cure technology on IES’s new super-high-speed VUTEk offering uses LED lamps to immediately pin drops of ink on the substrate during printing, followed by a traditional UV lamp cure as the substrate leaves the printer. This proven and innovative curing process offers better uniformity, color density, and a wider color gamut in high-volume throughput. EFI’s new CP5G ink delivery technology on the printer delivers complete ink circulation, superior dot placement, 5-picoliter drops and grayscale imaging – a robust feature set that can ensure IES and its customers gain fine text imaging and near-lithographic imaging with a four-color CMYK inkset.

The ink recirculation system is leveraged from EFI’s Nozomi single-pass inkjet printer architecture and ensures continuous flow of fresh ink, at the correct temperature, always at the ready. Users can also expect to obtain a yield of more than 1,800 square feet (168 square meters) per liter of ink – an ink yield increase of 30% to 50% compared to other inkjet sign and display graphics printers.

The EFI Fiery proServer Premium digital front end (DFE) drives IES’s new VUTEk XT printer, providing built-in production tools and industry-leading color management, along with EFI’s exclusive FAST RIP technology for accelerated file processing.

“IES never stops thinking ahead to the next innovation and the ways advanced technology helps both their employees and their bottom line,” said Ken Hanulec, vice president of worldwide marketing, EFI. “When our team consulted with Adam Ingram and his team about high-volume production for rigid substrates, it was clear that our new VUTEk XT printer had the power, and outstanding quality, needed to help IES maintain its competitive advantage. Great things are in store for this important customer as the world’s first user of our groundbreaking, new high-volume signage solution.”

With the VUTEk XT printer prepared to revolutionize IES’s print production, the business is ready to grow to new heights. “We want to see where the XT is going to take us,” said Ingram. “The sky’s the limit for us.”

_________________________

To become a subscriber, visit www.thecannatareport.com/register or contact cjcannata@cannatareport.com directly. Bulk subscription rates are also available upon request and included in our media kit.