Solimar Systems, a leading provider of workflow software solutions for print production and digital communications, today announced its commitment to the printing industry as a Silver Sponsor of the 2025 Inkjet Summit. This marks Solimar’s 11th year supporting this premier industry event.

The Inkjet Summit (April 14-16 in Ponte Vedra Beach, Florida) brings together senior-level executives and business leaders from across the printing industry to explore how production inkjet technology, software, and solutions can drive business growth and investment decisions. As a founding sponsor, Solimar Systems continues to champion innovation in the inkjet printing space through its Chemistry™ Platform.

“We look forward to meeting with many customers and partners at this boutique and unique conference,” states Mary Ann Rowan, Chief Experience Officer at Solimar Systems. “This event provides an invaluable platform for us to connect with industry leaders, present customer success stories, and showcase how our Chemistry Platform empowers organizations to maximize their investments in inkjet printers and presses through intelligent workflow automation.”

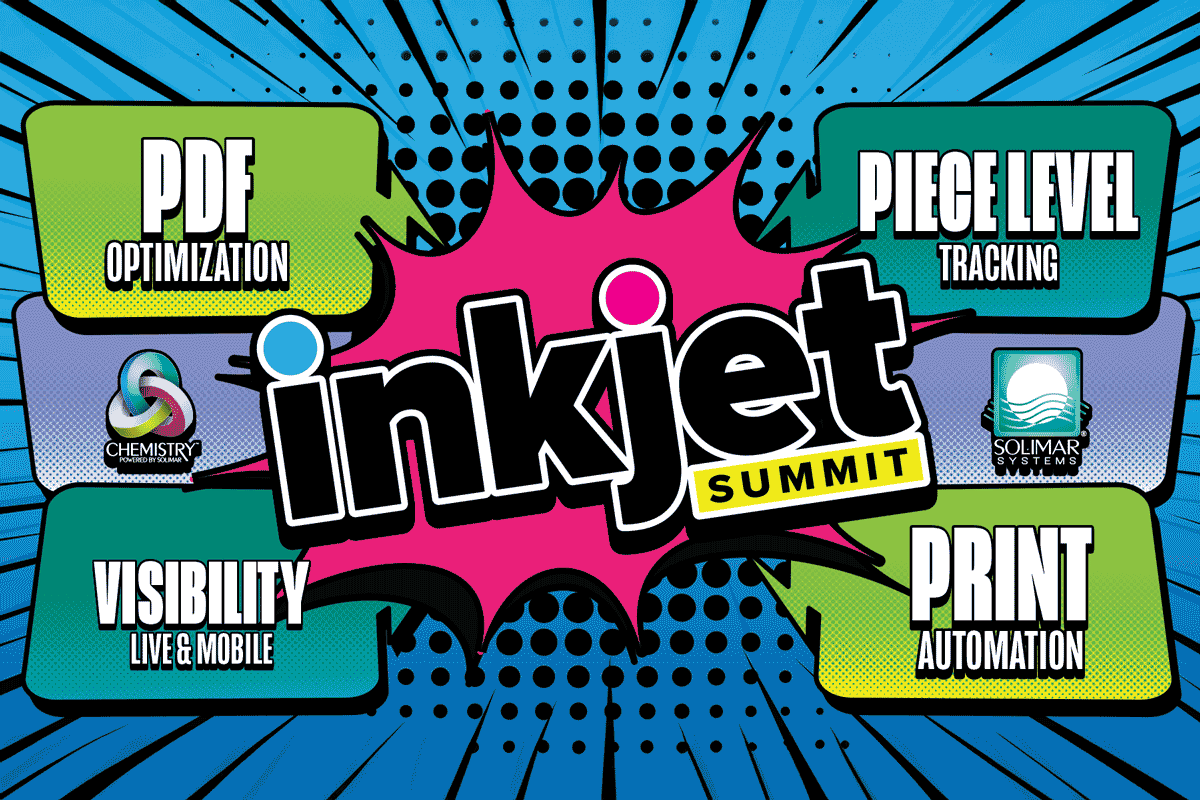

Solimar’s Chemistry™ Platform delivers comprehensive workflow solutions that help print service providers optimize their inkjet printing operations. The platform’s modular design enables organizations to implement tailored solutions that address specific challenges in production environments, including PDF optimization and data stream conversions, enterprise output management, including job and piece-level tracking, and seamless integration with existing hardware and software.

For inkjet users specifically, Solimar’s solutions provide critical capabilities that drive efficiency and ROI:

- Streamlined Workflows: Automate manual touchpoints to reduce production time and labor costs

- Enhanced Print Quality: Optimize PDFs and standardize output across multiple inkjet devices

- Piece-Level Tracking: Maintain visibility and integrity throughout the production print and mail delivery process

- Data Transformation: Convert legacy data streams to optimized outputs for print and electronic distribution

- Dashboard Visibility: Real-time production monitoring with alerts for improved decision-making