Mimaki brings versatility to textile printing with the TX300P MkII hybrid textile printer.

Above: Mimaki’s TX300P MkII hybrid textile printer can print pigment inks direct to fabric and dye sublimation

inks to paper in the same footprint.

Last year at ITMA, Mimaki unveiled its TX300P MkII hybrid textile printer, featuring a new hybrid-function able to print direct to fabric and to dye sublimation transfer paper using two different ink sets in the same printer. The printer is now starting to gain a foothold in North America for on-demand, short-run production.

According to Victoria Harris, senior textile segment specialist for Mimaki, one of the driving forces has been the demand for masks during the COVID-19 pandemic.

“Several customers have adopted this printer to be able to print on paper for heat transfer to polyester for gaiter and fitted masks,” she said. “They are also able to print direct to natural fabrics like cotton using pigment inks, all in the same footprint.”

The printer has a unique swappable platen system that allows users to switch between the two ink types in about two minutes. Harris noted that the printer has four channels running dye sublimation ink for printing on paper, and four channels of pigment ink for direct printing to fabric, wallpaper, and other substrates, making it extremely versatile.

“This is the world’s first commercial size digital textile printer that can print pigment inks direct to fabric and dye sublimation inks to paper in the same footprint,” she said. “With Mimaki’s pigment inks, you can print directly to coated and uncoated fabrics because of the binders in the ink that operate like a glue, gluing the ink to the surface of the fabric.”

Mimaki is not new to “world’s firsts,” having introduced the world’s first wide-format inkjet printer with water-based textile pigment inks back in 1998. Today, the company has a broad portfolio of textile printers and inks. While pigment ink is the Holy Grail of digital textile printing—because you can print to just about any fabric—there is still demand for other ink sets, particularly for printing high-end fashion or home décor items.

“Pigment inks are in high demand because of the ease of the process, but globally, most apparel goods and higher-end textiles are printed with reactive inks,” explained Harris. “Pigment inks have a different aesthetic; they sit on top of the fabric, while fiber-reactive inks actually become part of the fiber itself and can deliver a wider color gamut and the best wash fastness. It is a beautiful ink, but there is more required in the process, including washing and steaming post-print.”

To make it easier for producers to handle acid and reactive inks, Mimaki acquired Australian company Rimslow in 2017. The company features a complete line of textile pre- and post-treatment equipment, meaning that producers can acquire the complete solution from one source—inks, printers, and pre- and post-treatment in a compact, unified solution.

Above: threeASFOUR used reactive inks on silk to create pieces featured in its Spring 2021 collection produced on the Mimaki Tiger-1800B Mkll belt-type printer. Photography credits include: Collection by: threeASFOUR; Photographer: Elisabet Davids; Models: Kayla Scott, Joseph Gelpi at Ford Models, Kalah Christina; Stylist: Victoria Bartlett; Hair: Kenta Koda; Makeup: Chichi Saito

Mimaki put this to work in a collaboration with fashion brand threeASFOUR unveiled at Paris Fashion Week Spring 2021 and featured on Vogue.com.

“We produced all of the textile print designs in the collection,” reported Harris. “It’s beautiful, definitely worth checking out, [and they] primarily utilized our Tiger 1800B-MkII high-speed printer with reactive inks, on natural fibers like cotton and silk.”

Mimaki ran acid inks on its belt model.

“We coated all the fabrics in house, steamed them, and then washed,” explained Harris. “So [we] enabled the full process for direct-to-fabric printing to materialize the collection’s creative vision.”

Mimaki sells its textile printers through the dealer channel. “Ideally, textile dealers have expertise in printing textiles,” Harris says. “You can grow into that expertise, but having some knowledge about fabrics and digital printing of them is important when looking to become a textile dealer.”

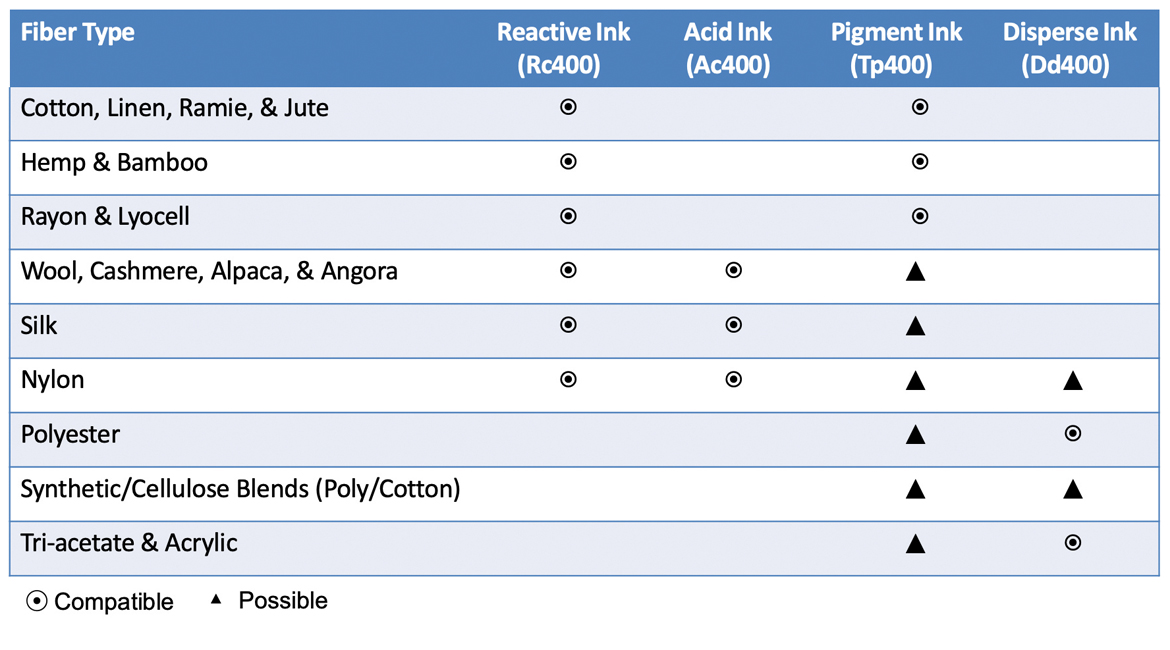

Above: The fabric types that can be printed with each of the Mimaki inks.

However, Harris does point out that with the growing number of sign and display graphics businesses producing soft signage, that can act as a stepping stone for moving into printing of textiles, apparel, and home décor items.

“The TX300P-1800 MkII is an ideal printer for making that transition,” she said. “It is an ideal entry level machine for short runs and sample production.”

The Tx300p-1800 MkII has the ability to run single ink configurations for reactive, acid, direct-to-fabric (DTF) dye sub, and pigment. The hybrid function feature allows for running a dual ink set in 3 different combinations listed below and is ideal for customized on-demand, short run production. The dual ink set combinations include:

- dye sub transfer paper & DTF pigment.

- dye sub transfer & direct dye sublimation.

- DTF Pigment & DTF dye sublimation.

The Tx300p-1800 MkII is recommended for e-commerce platforms, textile designers and agencies, brands (for sample production), maker spaces, and educational institutions. For sign companies that are already doing heat-transfer dye sublimation for soft signage, Harris noted that they would most likely choose a single-ink configuration since they already have dye sub heat transfer capabilities.

Caption: Victoria Harris, senior textile segment specialist for Mimaki

Caption: Mimaki’s TX300P MkII hybrid textile printer can print pigment inks direct to fabric and dye sublimation inks to paper in the same footprint.

Caption: The fabric types that can be printed with each of the Mimaki inks.

Caption: Pieces that were created as part of this project used reactive inks on silk and were printed by using the Mimaki Tiger-1800B MkII belt-type printer. This printer is available in either direct-to-fabric or sublimation transfer models.

Photography credits include:

Collection by: threeASFOUR

Photographer: Elisabet Davids

Models: Kayla Scott, Joseph Gelpi at Ford Models, Kalah Christina

Stylist: Victoria Bartlett

Hair: Kenta Koda

Makeup: Chichi Saito

[NOTE: These credits must be included]

Caption: The Tx300p-1800 MKII has the ability to run single ink configurations for reactive, acid, direct-to-fabric (DTF) dye sub and pigment.

Access Related Content

Visit the www.thecannatareport.com. To become a subscriber, visit www.thecannatareport.com/register or contact cjcannata@cannatareport.com directly. Bulk subscription rates are also available