The first-ever PRINTING United show was a resounding success.

Top: Attendance was brisk on the first day of the PRINTING United show.

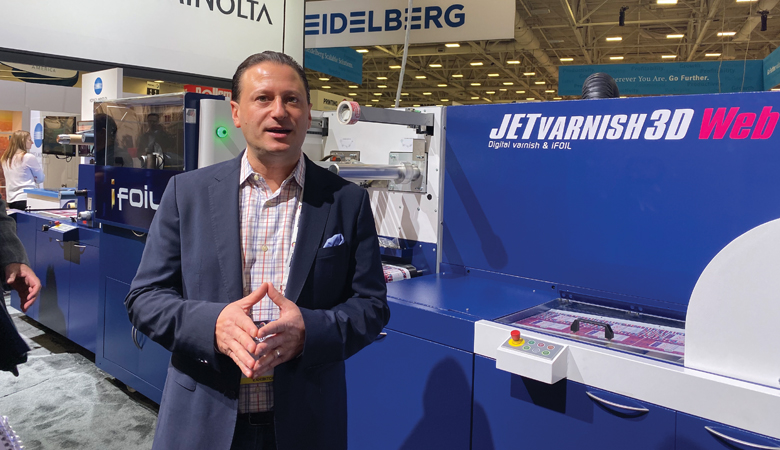

Above: Dino Pagliarello takes press and analysts on a tour of the Konica Minolta exhibit.

From October 22-25, CJ, Scott, and I attended what can best be described as a “buying show,” PRINTING United 2019 (formerly SGIA Expo). The target audience, in-plants and commercial printers didn’t just come to kick tires; they came to buy.

PRINTING United is 100% owned by SGIA, but through a partnership with NAPCO Media, has successfully built on the previous SGIA graphic, industrial, and garment segments, and extended deeper into the commercial, in-plant, and packaging markets.

Higher-Value Print

Above: The Konica Minolta booth had a storefront theme which highlighted the many possibilities for print.

Our approach to covering this show was to focus on the exhibitors most familiar to our audience.

Our first meeting was with Konica Minolta’s Kevin Kern, senior vice president, business intelligence services and product planning. He explained that Konica Minolta’s approach at the show was to focus on brand owners and graphic designers as much as printers.

“We are trying to put people in the position of offering new applications, which we think will drive higher-value print into print organizations,” said Kern.

Konica Minolta has a comprehensive range of equipment and software solutions to produce this higher-value print and as Kern pointed out, “We are fully invested in the business and continuing to invest.”

That was certainly evident in the company’s booth with devices covering the full range of Konica Minolta’s printing technologies. One highlight was the new AccurioPress C14000, the company’s fastest toner-based production press operating at a speed of 140 ppm. Kern pointed out that it was not the speed that impressed him as much as its ability to hold color reliably over long runs. This is accomplished via the IQ-501 Intelligent Quality Optimizer technology, which continuously monitors and adjusts color, density, tone, and registration settings with closed-loop, automated process controls.

We asked why the KM-1 was not at the show and Kern explained that it takes three weeks just to set up. Interested visitors were shuttled to a nearby customer’s facility for a demo. We later learned that a visitor from Mexico acquired a KM-1 after viewing a demo.

Customer Appreciation

Above: The Ricoh customer panel was an educational experience. Left to right: Andy Chagan, Mark Cohen, Brad Books, and Ricoh’s Gavin Jordan-Smith

The Ricoh press event included a customer panel, which often makes for an informative briefing. Gavin Jordan-Smith, senior vice president, commercial and industrial printing business, Ricoh USA, discussed the keys to the company’s growth and success.

“People, power, technology, and innovation are driving what we are doing today,” he said. “It doesn’t matter what the channel is, the value is carried forward through partnerships and alliances. It’s about inspiring the customer to do more.”

To get that message across, three customers shared success stories.

Brad Books, managing partner, Capitol Blue Print, explained that his family-owned business started in the engineering and architectural printing market, but that has radically changed. Blueprints now only represent 5% of his company’s total revenue. The company replaced two competitor’s monochrome machines with one Ricoh Pro 8200. Subsequently, they added a Ricoh Pro C7200e Graphic Arts color press to its lineup.

“Customers want quick turnaround,” said Books. “They want their jobs done in 2-4 hours, and they want it at a reasonable price, and with top-notch quality. Since adding the Ricoh printers, we can deliver on 2.5 out of the three.”

Andy Chagan, account executive, Tri-Win Direct, noted that Ricoh technology allows his organization to process high-volume direct mail jobs faster and more efficiently than ever before. He described a 50,000 piece-job that used to take 40 hours to produce, but now takes 6-8 hours on one of Tri-Win Direct’s two Ricoh Pro VC60000s.

For Mark Cohen, CEO and founder, MAC Specialties, which recently installed the first Ricoh Pro TF6250 flatbed press in the U.S., “We’ve gone all digital and we invest in faster turnarounds to meet demand. Push a button and out comes the product.”

We spoke with Jordan-Smith after the press conference.

“We want to build a better alliance (with dealers) by opening up as much as we can,” said Jordan-Smith. “Look at our booth, there are no walls.”

He wants dealers to understand where Ricoh is going in this high-end segment. A key focus is textile printing and applications such as truck wraps. Looking further out, Jordan-Smith revealed Ricoh is a decade away from a holographic screen for its devices.

Jordan-Smith is genuinely excited about the future of print.

“Between April 2019 and September 2019, 46% of the business has been with net new customers,” he said. “This is the result of the last 15 years of investment in digital printing. You either have to invest in new technology or you go away.”

We have known Jordan-Smith for several years. He is a highly capable and well-informed executive in production and industrial print. That is good news for Ricoh dealers.

Above: Ricoh showcased its latest wide-format technology.

A Year of Change

Above: The EFI booth was extremely busy on the first day of the show.

Next was the EFI Press Conference. This has been a year of significant changes at EFI, including a new CEO, a new vice president of marketing, and its acquisition by the private equity firm Siris Capital. These changes have EFI well poised to continue in a leadership position in technological development and addressing virtually all the key areas of industrial print.

Jeff Jacobson, who most recently was CEO of Xerox, took over as EFI CEO in August of this year. He opened the press conference on Wednesday by detailing his excitement about his new role and the company, and describing EFI as an anchor of the industry by the many roles it plays across printing processes. He told the audience Siris Capital knew exactly what it was buying when it acquired EFI.

“We spend 15% of our revenue on R&D every year and Siris loves that,” he said.

Jacobson was followed by Ken Hanulec, vice president of worldwide marketing. Hanulec is no newcomer to EFI, and we have personally known him for close to 10 years. He succeeded Frank Tueckmantel who left to become executive vice president of NAPCO. Hanulec spoke about EFI’s new products, the VUTEk h5 and the VUTEk 32h, which was shown for the first time at PRINTING United. On the soft signage side, Hanulec reported that the FabriVU 340i, a 10-ft wide dye-sublimation printer, has already exceeded 200 shipments.

After the press conference, we had an informal conversation with Jacobson who informed us that EFI was heavily into printing on corrugated materials because only 1% of the printers printing in that segment have upgraded to digital technology. Jacobson also offered kudos to former EFI CEO Guy Gecht who had been with the company for 30 years.

“He positioned us well for the next 30 years,” stated Jacobson.

Above: An example of printing on textiles at the EFI booth.

Water-Based Ink Solutions

At any print event, you can count on HP to be at the forefront of the technology. This show was no exception. Before PRINTING United, HP announced it is investing $200 million over the next five-plus years to develop water-based ink technologies for printing digitally on corrugated packaging and textiles.

In the industrial area, it is all about inkjet heads, inks, and media. Profitability is significant because of the high margins and the huge consumption of ink. Dealers can equal the revenue received from the hardware on the sale of ink in the first year.

An extremely important vertical for HP is food packaging. HP did not invest such a magnitude without believing very deeply that this represents short-term gain and long-term benefit. It is not only the ink as HP is also addressing the next generation of printhead and press technology.

Following our visit with HP at ITMA 2019 in Barcelona this past June, we asked HP to set us up with an executive who could discuss what HP was doing in textile printing. As we noted in our coverage of ITMA, HP is a virtual newcomer to this side of industrial printing. Henry Franceschini, Americas textiles category manager for HP, shared his vast knowledge of marketing and sales around textile printing.

“In textile printing, you utilize dye sublimation on sportswear,” he said. “If you want to print on products found in Bed Bath & Beyond the printing is on polyester.”

It is important to follow HP because they commit to developing the most difficult aspects of selling printers of any kind. For example, printing on cotton is very difficult. That is why 80% of all textile printing is on polyester. Franceschini explained that HP will eventually go to pigmented ink, perhaps in another two years, which will then make printing on cotton a reality. He also suggested we visit the retailer Kohl’s, explaining that virtually all the sportswear sold there is produced via dye sublimation. The advantage of the dye sublimation process is you can wash and bleach the garments with no loss of color.

But what does this mean to dealers?

As it was explained to us HP employs the term Hybrid Rep (which is direct). HP sells it and supports it. Dealers sell ink and paper. It does not appear HP has a program that makes sense for the dealers we know.

Entry Level Inkjet

We visited RISO and as always received a warm welcome from Andre D’Urbano, director of dealer sales and corporate marketing. In August 2019, RISO introduced a new brand of high-speed production inkjet printers. The first product, the VALEZUS T2100, is a high-speed, 320-ppm full-color cut-sheet printer. The machine sells in the $250,000 range and was the centerpiece of the RISO exhibit at PRINTING United. By the second day of the show RISO had orders in the double digits for this new model.

The VALEZUS is a product that can be sold to a commercial printer as a backup to a more expensive digital press. D’Urbano emphasized that RISO does not compete with Xerox, Canon, or Ricoh in the inkjet space. The VALEZUS T2100 can be easily deployed when multiple units are needed. RISO’s pitch to dealers is straightforward, sell the VALEZUS when customers are looking at larger machines as a defense strategy. In other words, if you are not selling production devices that are currently being offered, the RISO is a good place to start.

D’Urbano reported that RISO has successful relationships with OEM partners such as Kyocera Direct, Sharp, and Toshiba.

“We are looking to double our sales in the Americas and the only way for us to do that is with partners,” he said.

Innovative Technologies

Above: The Canon Océ Colorado 1640 had a prominent spot in the Canon exhibit.

Our appointment with a Canon executive was canceled because their flight was delayed. We wanted to see the new Océ Colorado 1650. Fortunately, we stopped by the booth and received an excellent demo from a Canon employee. We learned that there were two innovative technologies: the more flexible and stretchable formulation of the Canon UVgel 460 inks and the Océ FLXfinish technology. The new inks provide image stability even when folded, bent, or wrapped. And with the Océ FLXfinish technology, one can print with either a glossy or a matte finish, independent of media type. These new technologies build on a platform that already delivers durable prints as well as geometric and color consistency.

Quite a few Canon dealers are currently selling the Océ Colorado 1640 and if Canon will allow them to sell the 1650 as well, it is a no-brainer. The stretch capability makes it a winner when doing wraps.

Rave Reviews

We like to ask exhibitors what they think of shows like this and the reviews of PRINTING United were uniformly favorable..

“PRINTING United set out to create one environment centered on the convergence of innovations in our industry,” said Heather Poulin, senior director, marketing, commercial printing business, Ricoh USA. “Based on the traffic we had in our booth, from commercial printers to sign shops, and many in between, that goal was achieved.”

Access Related Content

Visit the www.thecannatareport.com. To become a subscriber, visit www.thecannatareport.com/register or contact cjcannata@cannatareport.com directly. Bulk subscription rates are also available.