This specialized category represents a multi-billion-dollar market.

What is industrial print? Marcus Timson, co-founder of FuturePrint and EcoPrint in the U.K., classifies it as not having the primary purpose of carrying a promotional message. “It’s print that is part of a manufacturing process that either enables the function of a product or enhances its appearance or decoration [from an aesthetics standpoint],” said Timson. In this specialized category of print, an image or material is applied to facilitate primary or secondary functionality that helps the product do its job, describes manufacturer Tapecon Inc.

Some industrial printing—such as thermal output from the barcode, label, and radio-frequency identification (RFID) printers manufactured by Zebra Technologies—requires rugged devices for harsh conditions. Functional printing has seen the development of new products as a result of the merging of several industry sectors, including printing, materials (substrate, dyes, and chemicals), and electronics.

Valued at more than $11 billion (USD) in 2022, the global functional printing market is poised to surpass $30 billion by 2032, forecasts Persistence Market Research. Rising applications in the printed electronics and radio-frequency identification (RFID) sectors are expected to drive the most growth, which is set to reach $10 billion in the U.S. over the next nine years.

So, how can office equipment dealers slice their piece of this mega pie? “The biggest thing is to make sure that the customer’s application is tested thoroughly,” noted Patrick Donigain, senior manager of marketing for Canon U.S.A., Inc. “Industrial print requires unconventional substrates, adhesives, or laminates. These applications may be used in much more challenging environments or be expected to last a much longer period of time.”

Additionally, there may be very specific regulations or certifications that need to be passed. In general, industrial print applications demand a higher level of testing than traditional print applications.

Three Areas to Make Money in Industrial Print

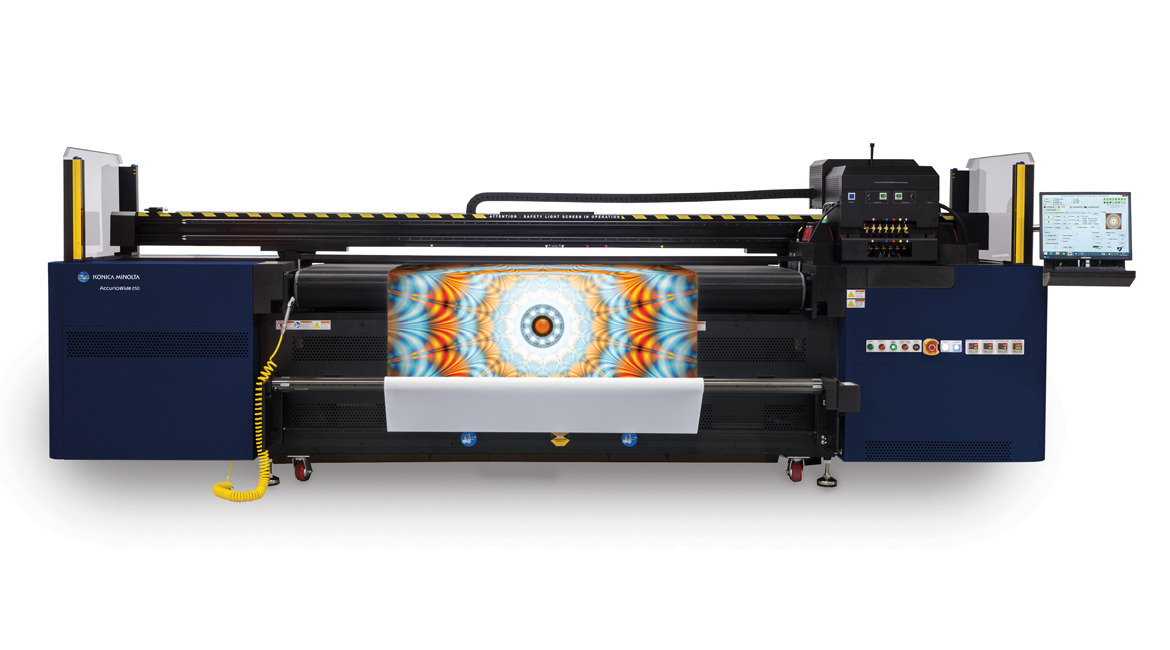

Konica Minolta Business Solutions U.S.A. divides its industrial print product offerings into thirds. “These three areas represent different ways of making money, yet they’re all still ways of printing on substrates,” explained Dino Pagliarello, senior vice president of product management and planning. “We view our high-speed inkjet developments as part of the industrial printing landscape.” That characterization includes the full-color AccurioJet KM-1 inkjet perfecting press. Launched in 2016, the B2-sized (23”x29”) sheetfed UV device can handle up to 3,000 sheets per hour.

The company’s second industrial print grouping centers on decorative, digital embellishment products, such as varnish and foil effects. Last October, Konica Minolta rolled out the JETvarnish 3D 52L, a B2-format digital embellishment press that targets a range of high-impact commercial and package printing applications. It allows printers, finishers, and converters to have an in-house, full production, and prototyping print embellishment system without screens, dyes, or plates.

The all-purpose, patented varnish formula allows for flat 2D spot UV highlighting and sculptured 3D raised special effects on a wide range of substrates (up to 600 GSM) from offset and digital inks to lamination films and aqueous coatings.

Finally, label printing comprises the third segment of the definition. The OEM introduced its AccurioLabel 400 label press in mid-2022. Since entering the digital, toner-based label space seven years ago with the AccurioLabel 230 model, Pagliarello reported that Konica Minolta has gained the No. 1 market share (33%) worldwide.

“The 400 doubles the production of the 230, and it features a white [toner] option,” he said. These label presses are built off Konica Minolta’s high-end AccurioPress C14000 production platform.

In March, competing OEM Toshiba America Business Solutions (TABS) launched its Duplex Linerless Thermal Printer, a first-of-its-kind industrial device that simultaneously prints a shipping label and packing list onto one dual-sided, linerless label.

For Canon, the industrial digital printing field encompasses labels and packaging for food, beverages, and household items. The Océ LabelStream 4000 label press, a web-fed, industrial-scale UV inkjet device with optional flexo printing, embellishment, and finishing units, launched in 2018 and was upgraded two years later. The LabelStream series was refreshed again last year when Canon acquired U.K.-based industrial press manufacturer Edale and incorporated its post-press cutting and processing technology.

Pathways to Industrial Print

Dealer owners and managers interested in adding either high-speed inkjet, digital embellishment, and/or label printing can count on Konica Minolta to get better educated on these product lines. The company has a dedicated team of salespeople and analysts led by Bill Troxil, president of Konica Minolta’s industrial print and production print business. “They can help dealers to adjust their business models appropriately and provide the necessary support to close, then service, the equipment,” said Pagliarello.

Canon’s Donigain added that there are publications dedicated to industrial printing that can be good educational resources for dealers as well. He’s also a big proponent of attending industry equipment expositions to see the latest applications in person.

Of the three industrial print applications, Pagliarello believes that the addition of label printing paves the smoothest market path for dealerships looking to diversify. The label business does, however, present a different sales strategy, he cautioned. Dealers selling cut-sheet toner devices have grown accustomed to cost-per-page (CPP) or one-rate contract models. “With labels, productivity is measured by calculating how many can fit up on a roll—meters per square inch,” he explained. The amount of toner coverage required factors into the consumables equation as well.

Price points and leasing terms can differ, too, of course. “The AcurrioJet KM-1 lists at around $1 million, so it’s not like financing a $30,000 production color device,” said Pagliarello. But, if the volumes are high enough, the return on investment is there, and it can make a lot of sense. “You really need to run that inkjet machine,” added Pagliarello. “Ganging B2, 8½-x-1-inch letter sheets, six up, can be the most efficient way to go.”

Industrial Print Applications

Canon’s Donigain pointed out that “many times, the cost of the printer is much smaller than the cost of other pieces of equipment used in the production of industrial print applications. If anything, we have noticed that as long the printer can produce the required output, the price point is not usually a stumbling block.” However, finding these customers can be difficult, which is why he recommended optimizing your web presence and ad words to include ‘industrial print applications.”

Digital embellishment is a unique value proposition, and Konica Minolta works hand in hand with its dealer partners to ascertain the best ways to market, build a customer base, and make money. While the OEM does not consider wide format output as part of its industrial print product portfolio, Pagliarello hinted that dealerships supporting package printing should watch for a new digital press that can print on corrugated media coming soon to North America.

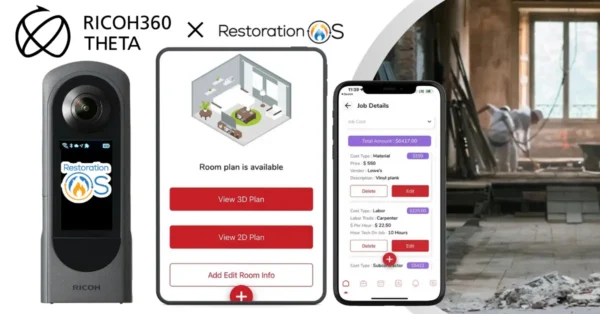

Dealers also can expect Ricoh USA, Inc. to be in the industrial-print mix later this year. The OEM’s related equipment portfolio should become available through the Ricoh independent dealer network before the end of 2023, reported Gavin Jordan-Smith, SVP, Ricoh Graphic Communications.