Looking for a print-oriented diversification opportunity? These devices are just the ticket.

As the office technology landscape evolves, dealers are exploring new avenues to diversify their offerings and boost revenue streams. One such opportunity is thermal barcode printers. Industries ranging from retail and healthcare to logistics and manufacturing use these devices. This potentially high-margin, high-demand product category can help dealers seeking to expand beyond traditional copiers and office printers.

For Tony Venice, director of product marketing at Toshiba America Business Solutions (TABS), the strategy is clear: Dealers should leverage their existing customer base to generate additional revenue streams through thermal printing solutions. “The way we look at it, it’s still in their wheelhouse,” said Venice. “We’re still talking about print. We’re not talking about selling bottled water or something ancillary.”

Servicing thermal printers also is a natural fit for a dealer’s service technicians. “Thermal printers are much less complex than the copiers and A4 devices that dealers are traditionally fixing,” observed Jay Schofield, senior business development manager, barcoding at Distribution Management. “Service is a component that all dealers are interested in from the start—they want to sell it, and they want to service it.”

Schofield described a typical success path for dealers entering the thermal printing market: They begin by focusing on service, followed by hardware sales, with supplies being the final piece. “Supplies are often the last component because they’re highly specialized and purpose-built for specific applications,” noted Schofield.

Distribution Management entered the thermal barcode label printer market eight-plus years ago with Zebra. Since then, the company has added Toshiba and TSC Printronix thermal label printers. Next month, Distribution Management will add Brother to the mix.

Applications Driven

Thermal barcode printers are used across various industries because of their efficiency, durability, and cost-effectiveness. Here are some typical applications:

Retail

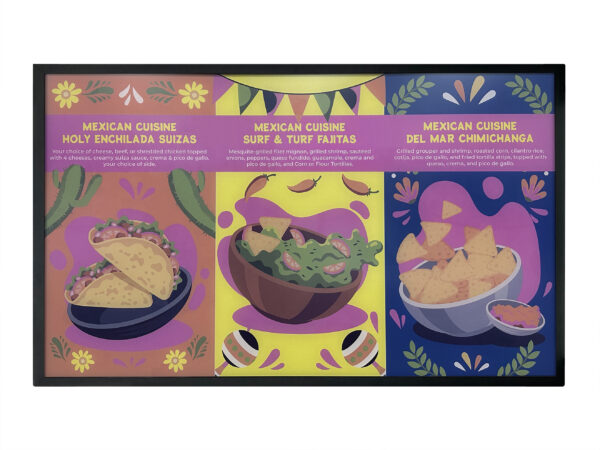

- Price Tags & Shelf Labels. Stores use thermal barcode printers to generate price tags and shelf labels for quick updates.

- Receipts. Many point-of-sale systems rely on direct thermal printers for fast, reliable receipt printing.

Warehousing & Logistics

- Shipping Labels. Direct thermal barcode printers serve as the standard for generating shipping labels due to their speed and low maintenance needs.

- Inventory Labels. Warehouses use thermal printers for product identification, bin labels, and stock tracking.

Manufacturing

- Product Identification Labels. Manufacturers use thermal barcode printers for part numbers, serial numbers, and tracking codes.

- Compliance Labels. Many industries require regulatory labels that include barcodes for tracking and safety purposes.

Healthcare

- Patient Wristbands. Hospitals use thermal barcode printers to create wristbands for accurate patient identification.

- Pharmacy Labels. Prescription labels with barcodes aid tracking and help reduce medication dispensing errors.

- Lab Sample Labels. Thermal printers ensure clear, scannable labels for blood samples, test tubes, and other specimens.

Food & Beverage

- Expiration Date Labels. Thermal transfer printing is ideal for producing long-lasting labels with expiration and batch numbers.

- Nutritional Labels. Restaurants and food manufacturers use thermal printers for printing ingredient lists and allergen warnings.

Transportation & Ticketing

- Boarding Passes & Baggage Tags. Airlines use thermal barcode printers for fast printing of travel documents.

- Event Tickets. Concerts sites, sports venues, and movie theaters use thermal printers for barcoded tickets.

Government & Public Sector

- Asset Tracking Labels. Government agencies and educational institutions use thermal barcode printers to track office equipment and supplies.

- Parking Permits & Citations. Law enforcement and municipal departments print vehicle permits and parking citations.

With such diverse applications for thermal barcode label printers, dealers can target a broad range of customers. “If you look at where some of the sweet spots are, dealers are very successful in healthcare facilities, as well as education, K-12, and in some cases, higher ed,” said Venice.

Why Dealers Should Consider Thermal Printers

Diversifying into thermal printers provides several advantages for office technology dealers, including the following:

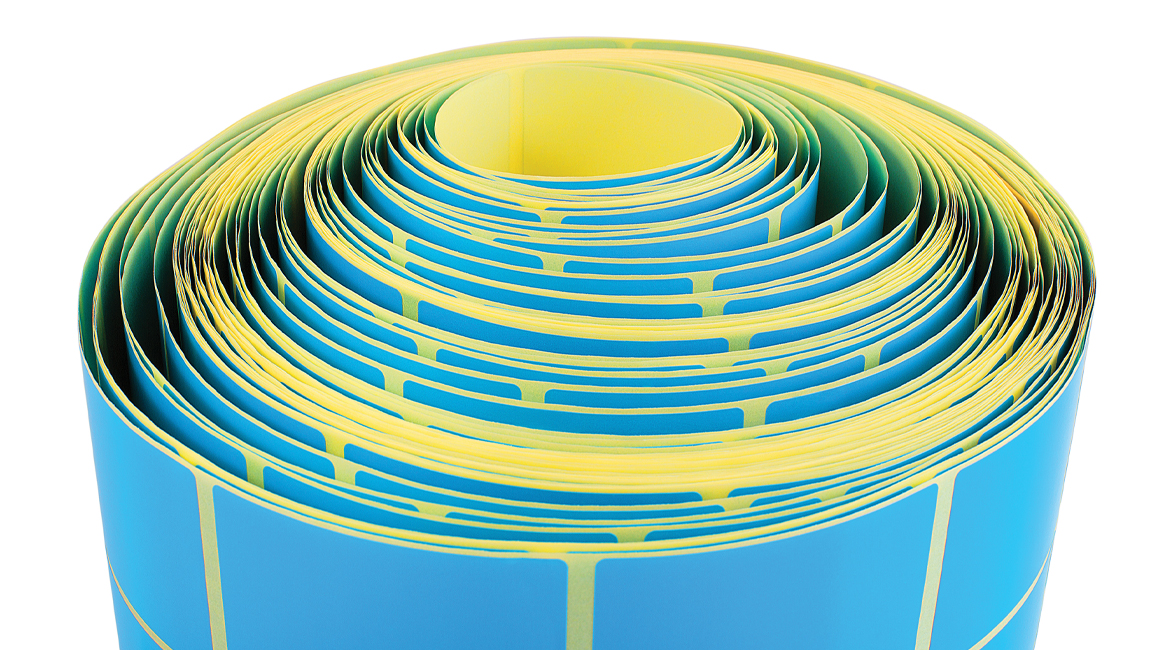

- Recurring Revenue. The need for consumables like labels and ribbons ensures ongoing sales opportunities.

- High Demand. With the rise of e-commerce, supply chain digitization, and regulatory compliance, the demand for barcode printing is growing exponentially.

- Cross-Selling Opportunities. Dealers can bundle barcode printers with other solutions, such as scanners and inventory management software, to create comprehensive packages for customers.

- Expanding Customer Base. Entering the barcode printing market allows dealers to target industries beyond traditional office environments, broadening their reach and revenue potential.

Venice described the opportunity as low-hanging fruit because it involves a dealership’s existing customers. And, like any other printing device in an organization, it requires management. “The opportunity’s there,” he said. “Whether they choose to go after it is ultimately up to them. But it makes so much sense for them to at least consider it and make it part of managing their customer’s fleets.”

Although thermal printers may not carry the same price tag as MFPs, Venice stressed the revenue potential in volume sales. “Margins for thermal printers are a little better than for the average MFP,” he said. “But again, the idea is you’re looking for opportunities to sell multiple printers. If you’re selling a dozen of these or 20 of these to a customer, it’s significant.”

Venice also suggested using quarterly business reviews to introduce these opportunities. “Make sure thermal barcode printers are part of your quarterly business review,” he advised. “This is incremental business with an existing customer, and we’ll help with that additional business.”

Through its partnership with Distribution Management, Zebra sees significant potential in partnering with office technology dealers, which bring a proactive approach to sales that traditional barcode resellers often lack. According to Schofield, copier dealers sell proactively, whereas thermal barcode printer resellers tend to wait for customers to report issues before selling them a new printer. This proactive model benefits Zebra and Distribution Management by increasing the refresh cycle of printers, boosting OEM consumables attachment, and reducing price transparency—factors that ultimately drive greater profitability and customer retention.

MPS and Thermal Barcode Printers

Distribution Management has played a key role in helping dealers navigate Zebra’s programs, most notably the Managed Print Spotlight Program, which provides significant benefits. “With the Managed Print Spotlight Program, dealers can receive discounts when selling in a managed fashion with a data collector on the devices and managing them,” explained Schofield. “It also allows them to fast-track their service authorization with Zebra.” Previously, dealers had to be Zebra partners for a year and build a fleet of printers before qualifying for service authorization. This program allows dealers to expedite the process and gain quicker access to service opportunities.

Although thermal printers lack embedded chips like traditional toner cartridges, advancements in reporting allow dealers to monitor label use and anticipate supply needs. According to Distribution Management’s Vice President of Sales Ted Gruener, Zebra’s newer Link-OS printers can seamlessly integrate into managed print services (MPS) programs and provide the dealer with valuable data insights. “We pull that data into our MPS program, allowing dealers to gain visibility into their customers’ print environments,” noted Gruener. “This visibility enables dealers to identify opportunities for refreshing aging devices and optimizing label supply management.”

With the ability to track thousands of printers within a customer’s environment, such as a hospital with a mix of older and newer devices, dealers can proactively plan for device upgrades and supply replenishment. “Once we analyze the data and a dealer shares it with us, we can help them map out a comprehensive refresh strategy,” said Gruener. “We can also plug in the correct labels and ship them proactively, enhancing operational efficiency for the end user.”

“We commonly sit down with dealers, review data collection assets, and help them identify opportunities they might not have considered,” added Schofield. However, he noted that many dealers remain reactive, only exploring barcode solutions when customers demand them. “End users are driving this push, and while we aim to be a catalyst for change, we wish more dealers would take a proactive stance,” he stated. He believes that starting with existing customers and gradually expanding into new markets can help dealers establish a strong foothold in the thermal barcode printer space.

One of TABS’ key initiatives is encouraging dealers to integrate label printers into MPS engagements. “We’ve been doing these educational webinars and sessions with BTA dealers to open their eyes to opportunities for label and barcode printers,” said Venice.

“Typically, when we do a managed print engagement, we do a discovery with FMAudit or one of the other tools,” continued Venice. “What kind of devices are on the network? And when you do that, you’re not looking for label printers. They will often be competitors’ products. So, we’ve been telling dealers that you should start looking to see if label printers are part of your customer’s fleet. And they’re starting to do this, and in some cases, there are a couple hundred of these things mixed in with all their Toshiba products and desktop and network printers, and nobody’s managing them.”

Venice sees this as a significant revenue opportunity. “Zebra doesn’t care because they’ve already sold them, and it’s not something that they focus on as far as managing those fleets. But a dealer, what we’ve been teaching them is, you could go in and take over management of those Zebra printers and manage those like you would with any laser printer MPS engagement and take over management of those thermal barcode label printers and provide maintenance and supplies, the same things you would do with an MFP or a network printer. And then, at some point when it’s time to refresh those printers, ‘We’d love for you to put a Toshiba label printer in there.’”

By leveraging MPS tools for thermal barcode printers, dealers can offer customers a unified approach to managing their entire print fleet, improving efficiency and reducing downtime. Integrating thermal printers into MPS programs provides a new revenue stream while also reinforcing dealers’ roles as strategic partners in their customers’ operations.