Konica Minolta spotlights production and industrial print with innovative showcase.

Above: The working printshop is the centerpiece of Konica Minolta’s CEC.

With 18,000 square feet, two stories, the latest innovations in LED lighting, a fully functional print shop, multiple meeting rooms, including space for a 100-plus person meeting, Konica Minolta U.S.A.’s Client Experience Center (CEC) has become a not-to-miss destination for Konica Minolta’s channel partners, as well as their customers and prospects. Visitors to the site in Ramsey, New Jersey, are engaged by product demos, meet with Konica Minolta personnel, and receive sales and service training. There is also office space for various Konica Minolta team members.

Above: The Cannata Report’s Scott Cullen (right) is greeted in the lobby of the CEC by Konica Minolta tour guides Maggie Grande, public relations manager, and Kevin Kern.

The CEC, which took four years to build from concept to occupancy, sets a new standard as a high-tech demonstration, training, and meeting facility. Opened at the height of the pandemic in May 2020, it eventually kicked into high gear in the latter part of 2020 and into 2021, offering virtual and in-person demonstrations of the company’s production and industrial print products.

Above: An aerial view of the two-story CEC lobby reveals oversized “output” displayed as visually arresting art, as well as a variety of modern seating options.

The design of the CEC was a highly collaborative effort, with team members from marketing communications and product marketing all contributing concepts and ideas ensuring that the facility was highly functional and not just a cool new building to house employees, have meetings, and showcase the company’s technology. The CEC includes the latest innovations in LED lighting while meeting rooms are arranged so spaces can be reconfigured as necessary, including the printshop. A second-floor meeting room with a black ceiling provides a cutting-edge look. Meeting rooms are located throughout the facility, enabling collaboration. An R&D space will also be located on site. A gallery room that leads into the printshop showcases samples of the output running off the production and industrial print machines, as well as its label printers. Although we can’t report the exact cost to construct the space, Kevin Kern, Konica Minolta’s senior vice president of digital transformation and emerging technologies, hinted that it was well into the seven figures.

Above: Still a work in progress, this second floor meeting room is set with comfortable seating and a striking black ceiling adorned with suspended hexagonal panels and unique lighting.

Not a Demo Room

The printshop isn’t as much a demo space as it is a fully functioning print facility, allowing printshop and in-plant customers to feel at home and view equipment and output in a real-world setting. “It doesn’t have the feel of a demo room,” observed Kern.

Above: The printshop

The printshop is humidity controlled, has tons of power outlets, and the electrical necessities to power these devices, just like in a traditional printshop. The room is mostly staffed by product managers and staff, whom Kern described as wizards on these devices. The space even has MOBOTIX cameras, a product segment that is growing like wildfire in the channel, according to Kern. Special LED lighting offers a higher color gamut than traditional LED lighting allowing even the most discerning printshop customers to get the best view possible of the printed output.

Above: There is ample square footage to house multiple functional MGI machines in the printshop.

The printshop floor showcases a what’s what from Konica Minolta’s production and industrial print, and label printer product lines. Here, you’ll see various versions of the AccurioPress, labeling systems, inkjet label presses, and the MGI JetVarnish, as well as EFI and CREO products. As new products are introduced, they’ll likely end up in the printshop prior to their formal introduction to the market. During our visit in July, we learned that some 1,200 square feet of space would soon be devoted to a new industrial print device that will likely be introduced by the beginning of next year.

As we walked among the equipment on the printshop floor, Kern referenced some of the products burning up the dealer channel. “We can’t make enough of the label products,” said Kern. “They’re selling so fast.” Also selling well, especially in the past year, is wide-format equipment for creating pandemic-related signage.

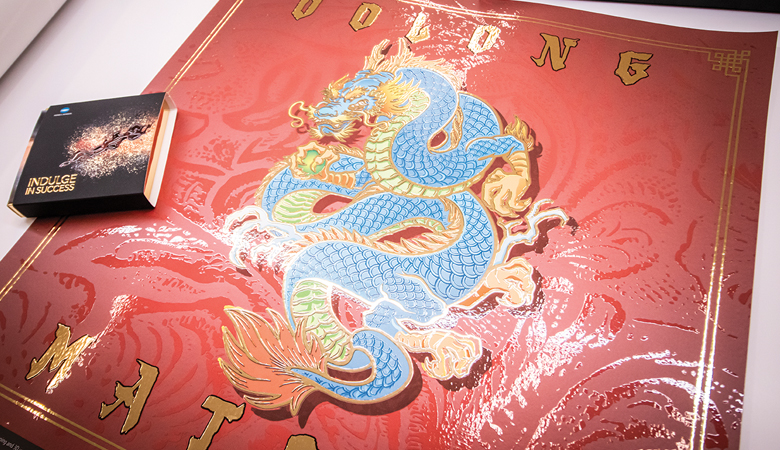

Above: Unique lighting, open shelves, and white display consoles create a pristine, contemporary setting to showcase the wide array of output from Konica Minolta’s industrial and production print devices.

The emphasis in the printshop doesn’t neglect the output, with much of it being color. Konica Minolta even has its own color expert on staff, Dr. Mark Bohan, director of color solutions, who is available to assist dealers and provide G7 training virtually and onsite. This is a differentiator. As Dino Pagliarello, Konica Minolta’s senior vice president of product management and planning, noted during a post-tour interview, it is unusual for an OEM to host G7 training.

Above: Sample output that was on display in the Printshop.

Tour Guides

June was a busy month virtually for the printshop. John Fulena, Konica Minolta’s director of production and industrial printing, dealer division, and his team conducted 27 30-minute virtual tours targeting 188 dealers. The goal of the virtual tours, according to Fulena, is to provide dealers a better understanding of the CEC and, more importantly, tell the Konica Minolta production/industrial print story, not just provide equipment demos. In addition, the CEC has hosted more than 30 in-person tours, including at least two with The Cannata Report. The feedback from dealers who have visited the CEC virtually or in person has been overwhelmingly positive, according to Fulena.

Above: Virtually every production and industrial print device sold by Konica Minolta can be found in the CEC’s printshop.

“Dealers are impressed with the products,” added Pagliarello. “When they walk in here, they don’t realize the breadth of the Konica Minolta offering. They’ve never imagined that we had so many different types of technologies, and to have them all in one place under one roof blows them away. It really solidifies the fact that we’re in the industrial production print space.”

Konica Minolta team members handle the general overviews while specialists on specific products are available for a deeper dive into the technology.

Constant Innovation and Evolution

The CEC is considered a work in progress. When we visited in early July, there were interior spaces not quite finished. One of those was a conference room that can accommodate up to 100 people.

Above: The Cannata Report’s tour ends with a photo op in front of a vast expanse of windows that provide an abundance of natural light to the interior no matter how the different spaces are configured.

“Overall, we’re very happy with what we’ve built, and we’re continuing to build out,” said Pagliarello. “I don’t think we’re ever going to be done. It’s always ‘Okay, what’s next?’ Whether it’s space that we’re updating or the technology we’re bringing in and people are training on, it will constantly be evolving. We’re going to continue to invest in things that allow us to be a true print shop. We can’t have equipment in there just sitting around, it needs to be running. We’re going to be making additional investments in personnel and software, including workflow. The goal is to further enhance the print shop experience and show printers this is how we do it and to take our best practices and implement them in their organizations.”

Pagliarello credits his colleagues in Japan with building the first CEC in the Tokyo area. Other CECs are being constructed worldwide, making these facilities a critical element of the parent company’s overall game plan. The various sites around the world collaborate quarterly to share best practices and suggestions for improving the functionality of these facilities.

Show and Sell

Some of Konica Minolta’s largest dealers have already visited the CEC this year, and Pagliarello expects going forward there will be a combination of virtual and in-person visits. “The positive effect of what happened last year is that people are very comfortable with virtual demonstrations,” said Pagliarello. “The pivot that the team did last year when the pandemic started to go one hundred percent virtual and having the showroom and the ability to do virtual demos really paid off. We’re much more efficient now that we can do both.”

In the past, Konica Minolta might have been able to schedule two major demos a day. With the virtual option, it can now offer between four and six demos a day.

The more dealers and customers who visit the space, the higher the expectations are for generating more sales. “In 2020, we did just a brief calculation on a direct correlation between customers that visited us virtually and sales,” explained Pagliarello. “We are well into seven digits in regard to equipment sales from when we started doing virtual demonstrations to the end of the fiscal year, which is pretty impressive when you’re not physically in front of a piece of equipment.”

The first time the customer and even the dealer saw the equipment was when it was delivered to the customer’s location for installation. The goal this year, now that the center is hosting more live and virtual visits, is to exceed last year’s results.

It was obvious throughout our visit and in conversation with everyone we spoke with, this facility is something special and will be as important to Konica Minolta’s future growth as the products it sells. One shouldn’t expect less from a facility built by one of the world’s top technology innovators.

Access Related Content

To become a subscriber, visit www.thecannatareport.com/register or contact cjcannata@cannatareport.com directly. Bulk subscription rates are also available.